Laser protection technology

Laser protection technology

JUTEC invests in research and development in order to set signals as a technology pacemaker in the field of laser protection.

As an owner-managed family company, JUTEC has stood for safety and quality for more than 25 years. Our customers benefit from our experience, as well as from the flexibility and speed with which we react to new challenges.An essential pillar of our success is the continuous further development and improvement of the existing, but also the creation of completely new, pioneering solutions such as the active laser protection system on a textile basis.

JUTEC will continue to invest in research and development in the future in order to continue to set signals as a technology pacemaker in the field of laser protection.

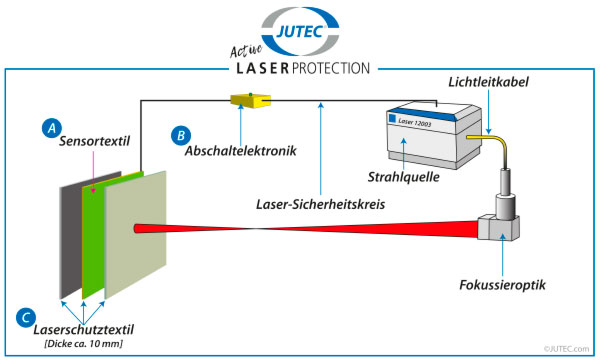

Active laser protection systems

More security and high flexibility.

Although the textile-based active laser protection system is only approx. 10 mm thick, it enables maximum safety. Through electrical integration into the safety circuit of your laser system, the active laser protection system switches off the laser when bombarded, so that no laser radiation is transmitted. The active laser protection system is delivered ready for connection.Technical data

Values

Wavelength range of the laser radiation

Intensity on the surface of the active laser protection textile

≤ 5,0 kW / cm²

maximum laser power

12 kW

Laser beam diameter according to ISO 13694 (86% method) on the surface of the active laser protection textile

> 5 mm

Operating modes

suitable for everyone

Emergency time-out of the entire laser system

≤ 120ms

Switch-off electronics TÜV tested according to EN ISO 13849-1: 2015

Performance level "e"

The maximum width of an active laser safety curtain is 1400 mm, the maximum height 4000 mm; The active laser protection system is designed so that several active curtains can be strung together. You can obtain the corresponding patch cables directly from JUTEC.

Your system will be assembled according to your dimensional specifications.

The active laser protection system is certified by an independent expert and checked by the professional association. It is attached either by loops, piping, eyelets or screws.

Passive laser protection systems

Our passive laser protection textiles always have the following characteristic properties:

- Completely silicone-free

- Mother-of-pearl-colored, diffuse reflecting laser-facing side

- certified by DIN Certco according to DIN EN 12254: 2012-04

- The light, mother-of-pearl-colored surface creates a pleasant ambience - and the high protection levels also allow you a wide range of uses

The multilayer ML-6 is black on the back and achieves the following protection levels certified by DIN Certco:

- D AB8 + IR AB3 + M AB6Y JUTEC 200-315 DIN-tested

- D AB6 JUTEC 316-1050 DIN-tested

- D AB5 JUTEC 1051-1400 DIN-tested

- I AB8 + R AB6Y + M AB7Y JUTEC 316-1400 DIN-tested

- D AB2 + I AB3 JUTEC 1401-11000 DIN-tested

The multilayer ML-6-2 is pearly colored on both sides and can be used on both sides. It achieves the same protection levels as ML-6.

The single layer ML-1 achieves the following protection levels certified by DIN Certco:

- D AB7 + IR AB2 + M AB6Y200-315

- D AB5 >315-1050

- D AB3 >1050-1400

- IR AB6 + M AB5 >315-1050

- IRM AB3 >1050-1400

Active or passive laser protection?

A general answer to this question can hardly be presented, so brief information should be given as to the boundary conditions under which active laser protection is indispensable from a safety point of view and under which circumstances the use of active laser protection enables economic advantages.

Laser protection walls for delimiting the laser area for hand-held laser systems are usually sufficiently dimensioned if they can withstand direct laser bombardment for a period of 10 s, this corresponds to test class T3. In many cases, passive systems are sufficient for this.

Automatic machines in particular, for example soldering applications in the automotive sector or powder deposition welding systems, are implemented in fully automated CNC systems that are not necessarily subject to continuous monitoring by an operator. The laser protection walls of such systems should correspond to test class T1 and achieve a service life of 30000 s (~ 8,3 h) in the event of laser bombardment.

The most important thing: the service life.

The service life of a laser protection wall is influenced, among other things, by:

- The power density of the incident laser beam. This results from the laser power and the beam divergence

- The distance between the processing optics and the laser protection wall.

If the distance between the laser protection wall and the optics is so large that the power density on the laser protection wall reaches correspondingly low values and falls below the protective limit radiation, passive laser protection walls can offer sufficient safety. This is the case even with high-power lasers with optics with large beam divergence. Above all, fiber and disk lasers in the common wavelength range of 1030 ... 1070 nm provide very high beam qualities (and thus a low beam expansion), which means that the distance between the laser protection wall and the optics would be disproportionately large to always be included in test class T1 for automatic machines passive protection system, so that active systems are preferable.

The active laser protection systems basically offer two advantages:

- Increase security.

- Reduction of space requirements.

The active laser protection system from JUTEC can easily be integrated into the existing passive laser protection device. This allows the existing laser protection infrastructure (e.g. laser protection cabin) to continue to be used, even if the laser protection wall has to be upgraded to meet higher demands on the stability of the laser protection wall.

By the way: Active laser protection can not only make an important contribution to increasing safety and reducing space requirements in (walk-in) laser cabins, but also in smaller automated cells for laser (micro) processing that have medium to high laser powers.