Laser protection systems

High-tech solutions for high-tech applications

Laser protection systems offer the necessary protection for people, machines and the environment in all situations.

When it comes to laser protection, we differentiate between passive and active solutions. Passive laser protection generally enables short-term protection against laser radiation. Passive laser protection solutions were an adequate solution, especially at the beginning of the laser age. This still applies to lasers with low power or to some applications in the observed operation.

In recent years, however, the available laser power has increased so much that passive laser protection solutions are reaching their limits.

JUTEC has recognized this trend and is offering textile, active laser protection solutions for the first time - tested for high-power applications up to 12 kW laser power.

What do we mean by active laser protection?

The textile, multi-layer laser protection structure ML-20 contains a sensor layer. This sensor position is looped into the safety circuit of your laser system via measuring electronics. If the system breaks down and the laser beam is focused on the protective device, it switches the laser off.

Our active laser protection system is particularly user-friendly and easy to install. You can currently find it in the following of our products:

- Active system protection

- Active laser safety curtains

- Active laser protection swivel arm frames

- Active laser protection partitions

The active laser protection system also offers you the option of RetroFit. Your existing, passive laser protection cabin is simply activated within a very short time. If desired, only locally where things get tricky and passive protection does not offer any security.

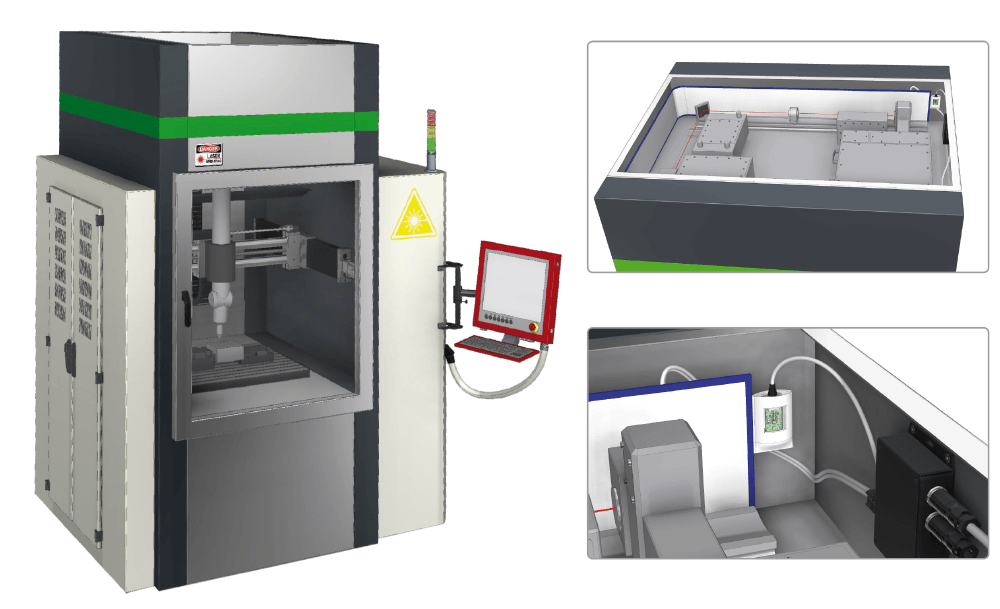

Active system protection

For fully automated 2D or 3D laser processing systems.

Fully automated systems must have a shutdown device so that exposure to laser radiation cannot occur even in the event of an accident. An accident occurs e.g. This occurs, for example, when the machining process is unintentionally interrupted while the laser cannot be switched off; a mirror in the beam guide fails, so that the laser beam leaves the planned beam path.

In this case, the active laser protection system offers the necessary protection by positioning it at the points where the laser beam can potentially hit. In the event of a mirror break (e.g. due to mechanical damage), the laser beam hits the active laser protection textile and the laser is switched off.

Active laser protection for fully automated 3D robot systems.

Active laser protection textiles can also be used in the enclosures of laser processing systems. This is particularly useful if it is a fully automated 3D processing system and the laser beam can hit the walls of the housing in the event of an accident or unplanned destruction of the workpiece by the laser.

- Assembled according to the space requirements of your system

- Local equipment of particularly endangered areas

- Competitive advantages for you and your customers

- Shutdown of the laser source by opening the safety circuit

- Simplified acceptance of the processing system; Take active laser protection textile into account during construction

Retro fit

With an active laser protection system, for easy retrofitting of your laser cabin.

If you want to convert your processing process from a CO2 laser to a modern fiber or disk laser, or if you simply use a more powerful laser, the requirements for laser protection increase significantly.

By retrofitting your laser cabin with the active laser protection textile, there is no need to build a new cabin or cost-intensive conversion of the cabin, as particularly vulnerable areas can easily be retrofitted with the active laser protection textile. During laser fire, e.g. B. due to a system accident, the active laser safety curtain switches off your beam source - the dangerous situation is over. We tailor the dimensions of the active laser protection textiles to your needs.

Of course, JUTEC offers complete retrofitting - starting with advice, adapting our system using the latest CAD software, installation and acceptance by an expert, so that the CE of your system is retained. Retrofits typically take less than a working day, meaning there is little downtime for your system.

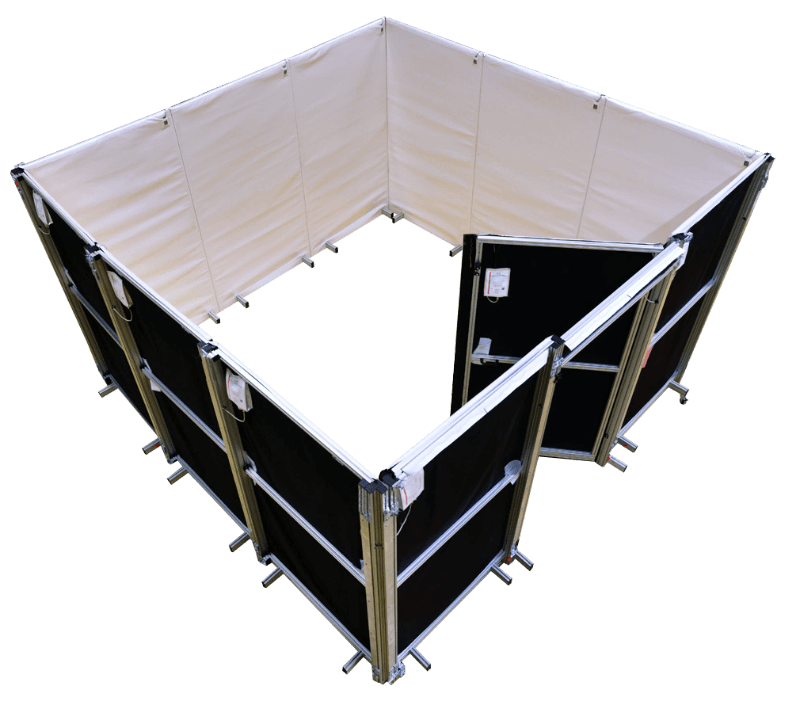

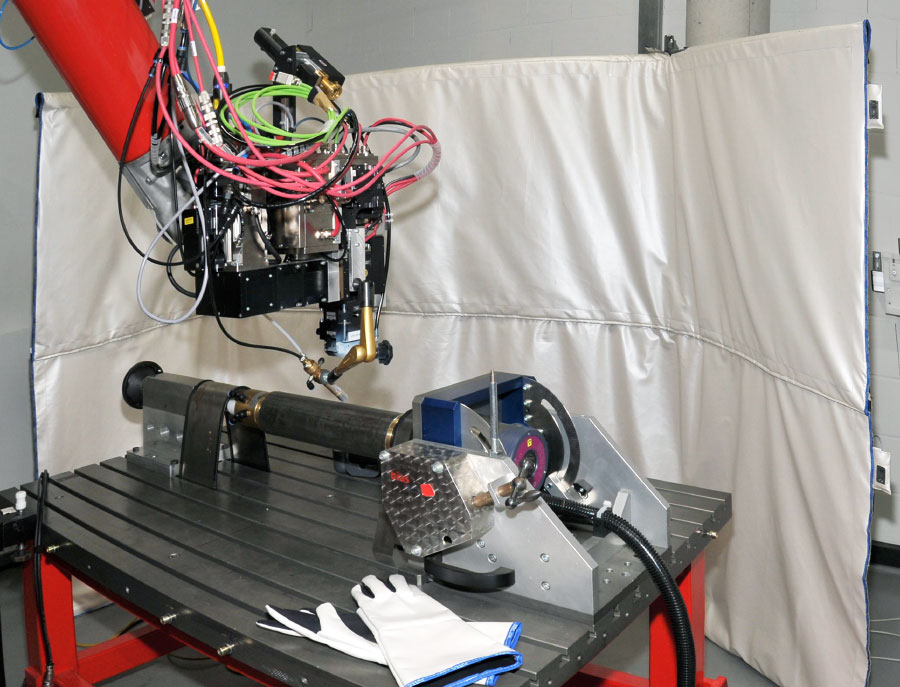

Mobile laser safety cabin

Limitation of the laser area and protection of surrounding employees.

Mobile (hand-held) laser devices are now so flexible that they can be used in almost any production environment. The size of the laser device allows the laser to get to the workpiece and not the other way around. It is now time to provide laser protection that is just as mobile and flexible as the laser source.

The mobile laser cabin - which is available in both active and passive versions - helps you to limit the laser area so safely that surrounding employees are not restricted in their activities by working with the laser. Depending on the modular design of the cabin, roof modules are also optionally available so that the laser area is protected from all sides. This is particularly important in high, spacious halls when not all entrances (e.g. to galleries) can be closed.

The cabin can be equipped with the active laser protection system ML-20 or the passive laser protection textile ML-6.

Dimensions: height 2.250 mm, module width 1.100 mm (other dimensions on request). The proven size is 3 x 3 modules. Interior space approx. 3.300 x 3.300 mm².

- Tool-free installation within <10 min (3.300 x 3.300 mm² cabin)

- Adaptable to size due to modular structure

- Easy to handle, rollable, one operator is enough

- Easy maintenance thanks to the modular concept

- Security through integrated door contact switch

- Protection concept checked by BG ETEM

- Door module equipped with laser protection window (optional)

- Pluggable lighting system (optional)

- High laser protection levels, tested by DIN CERTCO

laser protection screen

Mobile swivel arm frame with active or passive laser safety curtain.

The mobile swivel arm frame with active laser protection is used where mobility and safety are required. With active laser protection, you also protect mobile and stationary laser systems with outputs of up to 12 kW. The combination of the passive laser safety curtain ML-20 and the mobile swivel arm frame on castors is ideally suited for temporary laser protection in mobile laser applications. In order to be able to protect your application in the best possible way, different heights and widths are available as standard.

- Mobile frame for maximum flexibility

- Swiveling boom

- Very good brightness thanks to mother-of-pearl-colored, diffuse reflective surface

- Several swivel arm racks create a completely closed area

Active execution:

- Easy integration into the safety circuit (SIK)

- The green status LED signals that it is working properly

- Several active systems can be connected in series using patch cables

- Protection against direct fire and scattered radiation

- Particularly suitable for mobile laser systems and high-power lasers up to 12 kW

- Dimensions of the active swivel arm frame:

- Height mm 2.070

- Total Width mm 4.000

- Length of the swivel arms each 1.050 mm

Passive execution:

- High laser protection levels, tested by DIN CERTCO

- Dimensions:

- Heights 2.070 // 2.570 mm

- Total widths 4.000 // 4.550 // 5.000 mm

- Length of the swivel arms each 1.050 mm

Laser safety curtain

Passive laser safety curtain to protect laser areas in laboratories and medical facilities.

The multi-layer protective curtain ML-6 consists of diffusely reflective and non-flammable fabric. This is suitable for use in laser areas in laser classes 3B, 3R, 4 or 1.

NEW 2021: Also available as a variant ML-6-2 that can be used on both sides.

The suitability of the laser safety curtains for the respective application is subject to the individual examination of the laser specifications and is the responsibility of the laser safety officer on site. We would be happy to support you in this. As a light-tight material, the curtain is suitable for laser wavelengths from 200 to 11.000 nm in the medium power range and is certified according to the DIN EN 12254: 2012-04 standard for shielding at laser workstations.

Equipment:

- Height and width of the curtain according to your requirements

- High mechanical flexibility

- Easy to clean thanks to the closed surface of the curtain side facing the laser

- Very good brightness thanks to mother-of-pearl-colored, diffuse reflective surface

- High laser protection levels, tested by DIN CERTCO

- Completely silicone-free (no outgassing)

- Low weight per unit area of approx. 1.200 g / m²

- Fastening options: ceiling rail, loop, eyelets / rings, Velcro, piping.

You can attach the passive laser safety curtains very well using high-quality aluminum ceiling rails and ball-bearing gliders - which you can obtain from JUTEC. If desired, our partner will install the complete system, including fastening materials, at your location.

Test results ML-6:

- D AB8 + IR AB3 + M AB6Y JUTEC 200-315 DIN-tested

- D AB6 JUTEC 316-1050 DIN-tested

- D AB5 JUTEC 1051-1400 DIN-tested

- I AB8 + R AB6Y + M AB7Y JUTEC 316-1400 DIN-tested

- D AB2 + I AB3 JUTEC 1401-11000 DIN-tested

Laser protection roller blind

For areas with low laser exposure.

Due to its thickness of less than 1 mm, the single-layer laser protection curtain ML-1 is particularly suitable for applications that require maximum mechanical flexibility. The laser protection levels are significantly lower than with the multilayer passive laser protection curtain ML-6.

ML-1 is very popular for the equipment of laser protection roller blinds, where the exposure to laser radiation is rather low. As a light-tight material, it is suitable for laser wavelengths from 200 to 1.400 nm in the medium power range and is certified according to the standard DIN EN 12254: 2012-04 for shielding at laser workplaces.

Test results ML-1:

- D AB7 + IR AB2 + M AB6Y200-315

- D AB5 >315-1050

- D AB3 >1050-1400

- IR AB6 + M AB5 >315-1050

- IRM AB3 >1050-1400

- Height and width of the curtain or roller blind according to your requirements

- High mechanical flexibility

- Easy to clean thanks to the closed surface of the curtain side facing the laser

- Very good brightness thanks to mother-of-pearl-colored, diffuse reflective surface

- Medium laser protection levels, tested by DIN CERTCO

- Completely silicone-free (no outgassing)

- Low weight per unit area of approx. 450 g / m²

- Fastening options: ceiling rail, loop, eyelets / rings, Velcro, piping.

- Dimensions of laser protection roller blinds: widths up to 5.500 mm (special version up to 7.000 mm), heights up to 9.000 mm, corner systems possible

- Electrical or mechanical actuation, voice control, gesture control, ...