Heat Protection

Protection where things get hot

Wherever work is being done, chips fly. Of course, this also happens with flexing, grinding and welding work. JUTEC offers the ideal heat protection to protect people, machines and the environment in the form of splash protection blankets, heat protection fabrics, curtains, flame protection mats, pipeline construction mats, welding protection mats, foundry mats and much more.

Technical textiles for high temperatures up to 3.000 °C

Heat protection fabrics made of glass and silicate fibers with special coatings offer the perfect protection in a wide variety of compositions.

The fabric specifications define: sliding resistance, mechanical resilience, abrasion resistance, water impermeability, etc. This is achieved in material thicknesses from 0,2 mm to 3,0 mm in weight classes from 200 g/m² to 3000 g/m².

Depending on the area of application, JUTEC achieves textile heat protection up to 1.600 °C. Flame retardant pastes, also incorporated into mats, round off the range up to 3.000 °C and offer the safest protection in the event of direct flame contact.

Splash protection covers

Spatter protection blankets prevent fires from occurring due to welding or flex work with guaranteed protection up to 1.300 °C.

The simplest measure to prevent incipient fires during welding or flex work is to cover flammable areas with a classified spray protection blanket from JUTEC.

Special coatings in combination with density and thickness create a wide range of mechanical stresses and offer you reliable protection up to 1.300 °C.

Welding curtains

Welding curtains as heat-resistant environmental protection

When carrying out welding and flex work, there is a risk that flying sparks, weld beads and flex spatter can develop into unobvious smoldering fires in the immediate, unprotected working environment. This possible fire hazard must be ruled out. It is also important to avoid flashing the eyes of uninvolved employees.

Our curtains are produced in every width and length, also in slat form with and without viewing strips. Hanging/extending is achieved using hooks, eyes, loops, rings and snaps.

- Protection against flying flex, sweat and metal splashes

- Prevention of smoldering fire

- Ideal as a room partition, cabin or curtain

- Optionally with viewing window

- Made to measure according to customer specifications

- Temperature resistant from 250 ° C to 1.300 ° C

Covers

They protect against weld spatter and flying sparks and save expensive dismantling

Machines, engines, control cabinets and aggregates, etc. are completely covered. JUTEC protective covers are used precisely and individually in various new construction and repair projects.

In shipbuilding, power plant construction, etc., already painted parts can be installed, although welding or flexing work is being carried out in the immediate vicinity. We also manufacture hose, pipe and cable protection.

Your personal heat protection

Our field of activity in heat protection is so diverse that it is only possible together with our customers to achieve the highest level of security. From this common ground we develop problem solutions and expand our range of services on a daily basis. What we can do for your individual heat protection:

- Made to measure using modern sewing and cutting technology

- Largest possible choice of materials

- Service and advice on site

- Experienced and competent employees in the office

The following product groups (right-hand side) are intended to provide inspiration for what is currently in use. Let yourself be inspired and take advantage of our expertise.

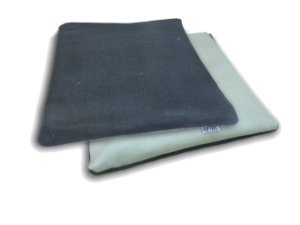

The welding cushion serves as a seat and knee pad in deep/narrow work areas. It protects when working in hot containers or at the highest ground temperatures.

Its design ensures that it can be used at floor temperatures up to 500 °C.

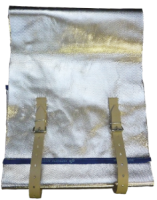

It is known as a weld seam cover mat in pipeline construction. This type of coating protects the weld seam from cooling too quickly. It prevents stress cracks from appearing and keeps moisture and cold away. The pipe can be placed in the ground in a protected manner.

Several locking systems, lengths and widths are available.

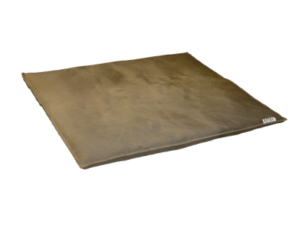

This type of mat is used as a base or to cover foundry products. For large castings with multiple openings, the mats are used to close them.

Advantage: A slower cooling is achieved and the interruption of the heating process leads to interesting cost reductions.

These mats absorb temperatures of up to 3.000 °C during welding, soldering or cutting work without transferring the heat to the substrate. This makes soldering and welding work less dangerous and there is no damage to the surrounding area.

Our proprietary pastes are ideal for welding and soldering, e.g. B. Heating cables up to 3.000 °C. The paste prevents the flow of heat within the material being processed. This also applies when processing thin sheets/sheets; one-sided application is sufficient.

A fire blanket in accordance with DIN EN 1869 works when fighting fires by depriving them of oxygen. It is part of the basic equipment of workplaces at risk of fire. Easiest handling through handle pockets and special folding are given. Suitable for enveloping burning people. Required when suffocating incipient fires.